For wiring-challenged kiln builders

BNQ-T9

A number of folks have expressed concern about properly wiring a temp controller for their kiln. While a bit more expensive than a digital controller that you have to wire, this one is foolproof. For controlling a kiln heat source, such as a Crockpot, or even much higher wattage, this controller from BN-LINK requires setting only two values: the heat cutoff value (the set point, which for my kiln would be 128°F) and the "turn back on" value (heat differential, which for my kiln is a hysteresis of 5°F, turning the heat back on when the temp falls to 123°F). You would use just the upper outlet (heating), since the lower outlet is intended for regulating a cooling device.

So...set your max temp, then set how far below that the power should come back on. That's all there is to this.

This hefty, solid object is designed for greenhouse heating and cooling (15A/1875W), and plugs into a US standard grounded outlet. It has a built-in overload cutoff. The best feature, which they don't advertise, is that once you enter the settings you desire, the BNQ-T9 continues to remember them, even after the power is cut off (say during a winter storm). Once the power is restored, your settings are still there, and the controller resumes functioning.

www.bn-link.com

www.bn-link.com

$36 plus shipping.

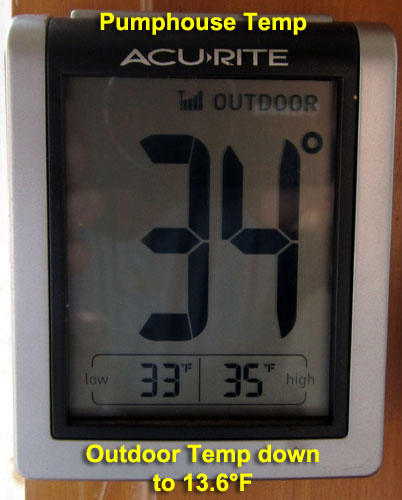

I bought one of these to regulate the small heater within my well pump house, to prevent the pipes there from freezing. It dawned on me, with its simplicity, how attractive a solution that might be for builders of tobacco kilns. It is designed for indoor use, though the temp probe is waterproof. So it would be mounted outside the kiln, with the temp probe inside the kiln. The Crockpot cord can be passed through the kiln wall, and simply plugged directly into the upper outlet of the BNQ-T9.

Bob

BNQ-T9

A number of folks have expressed concern about properly wiring a temp controller for their kiln. While a bit more expensive than a digital controller that you have to wire, this one is foolproof. For controlling a kiln heat source, such as a Crockpot, or even much higher wattage, this controller from BN-LINK requires setting only two values: the heat cutoff value (the set point, which for my kiln would be 128°F) and the "turn back on" value (heat differential, which for my kiln is a hysteresis of 5°F, turning the heat back on when the temp falls to 123°F). You would use just the upper outlet (heating), since the lower outlet is intended for regulating a cooling device.

So...set your max temp, then set how far below that the power should come back on. That's all there is to this.

This hefty, solid object is designed for greenhouse heating and cooling (15A/1875W), and plugs into a US standard grounded outlet. It has a built-in overload cutoff. The best feature, which they don't advertise, is that once you enter the settings you desire, the BNQ-T9 continues to remember them, even after the power is cut off (say during a winter storm). Once the power is restored, your settings are still there, and the controller resumes functioning.

Digital Heating and Cooling Professional Thermostat Controller -40-176°F 15A/1875W BN-LINK

Features ✓ DUAL OUTLET, DUAL FUNCTIONALITY: Our controller is capable of controlling a heating and cooling device simultaneously ✓ SET AND GO: Simply set the temperature probe, plug-in the controller, and use the large 6-button interface to choose your desired temperature setting. Digital...

www.bn-link.com

www.bn-link.com

$36 plus shipping.

I bought one of these to regulate the small heater within my well pump house, to prevent the pipes there from freezing. It dawned on me, with its simplicity, how attractive a solution that might be for builders of tobacco kilns. It is designed for indoor use, though the temp probe is waterproof. So it would be mounted outside the kiln, with the temp probe inside the kiln. The Crockpot cord can be passed through the kiln wall, and simply plugged directly into the upper outlet of the BNQ-T9.

Bob