3. Shredding

Most home-rollers of cigarettes tend to make up 20 or more cigarettes at a time. This places a time demand on tobacco shredding tasks. In addition, most prefer a fine or very fine tobacco shred, which is not practical using scissors, a knife, or a chaveta. So some form of mechanical shredder is required. Given the demand that will be placed on a shredder, purchasing a purpose-designed shredder is more cost-effective than attempting to get by with a pasta shredder or paper shredder, neither of which are designed for the unique challenge of shredding whole leaf tobacco. One can certainly just allow tobacco leaf to go out of the case, then shatter it into “flakes” with a food processor or similar kitchen tool, but you end up with random flake size, and an awful lot of dust (that used to be the fine quality tobacco leaf that you paid for).

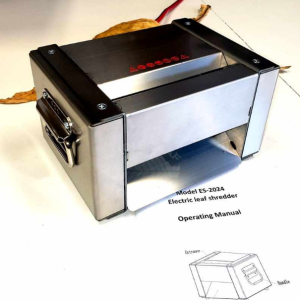

Mechanical tobacco shredders come in two general categories: electric and hand-cranked. The latter can sometimes be fitted to a variable speed, hand-held drill to power it.

Electric shredders are the least hassle, though their switches etc. do eventually require replacement, either at the factory or at home, with components purchased from the factory. Repair at home requires some skill with managing shaft bearings of different kinds, as well as wiring and other electrical matters. These shredders typically produce a shred of 0.8 mm width or somewhat finer. They typically shred faster than the user can stem leaf to feed into it.

The crank shredders come in “budget” and “heavy-duty” models, with a shred width of 0.8 mm or a wide shred of 1.5 mm. They are designed to be clamped onto the edge of a table, counter, or shelf or use.

With all shredders, the leaf fed into them needs to be stemmed—the hard, central vein removed to within a couple of inches of the leaf tip. For Oriental leaf, their diminutive stems do not need to be removed prior to shredding. While the shredders can eat stems on occasion, it deposits sharpened chunks of the stem into your shred and significantly shortens the lifespan of the shredder (both blades and bearings).

Ideally, the leaf to be stemmed and shredded is in low case (somewhat noisy, but does not crumble when handled). Drier leaf (out of the case) will shatter while being stemmed, and while being shredded. The moister leaf may shred well, but will more rapidly gum up the cutting blades.

For all shredders, the mechanism should be turned in reverse after a shredding session, to remove some of the particulates that have adhered to the blades. Some users regularly finish up with a dose of vodka or beer into the cutters, to clean them. Instead, use hot water to clean the shredder cutters followed immediately by thoroughly drying the shredder using a hairdryer. An additional approach is to follow the tobacco shredding session with shredding some stiff, bright white paper—the color being useful in making sure all the paper is cleaned from the cutters prior to next use. [Heavily finished copy paper contains a coating of rolled clay that may come off in the cutters.]